- Fleshing out the science with enough clarity to build a lab-scale plant in Denmark. This was completed in 2011.

- Leverage the knowledge gained from the Lab-scale plant to create the Pilot Plant. Completed in 2013. These first two steps were completed in conjunction with Aalborg University’s Department of Energy Technology.

- Define and file patents to achieve protection in the marketplace. Steeper has over 140 patents across 15 patent families. A significant slate of additional patents are pending.

- Build a first generation HTL Demonstration Plant. Construction of this plant was completed in Nov 2021.

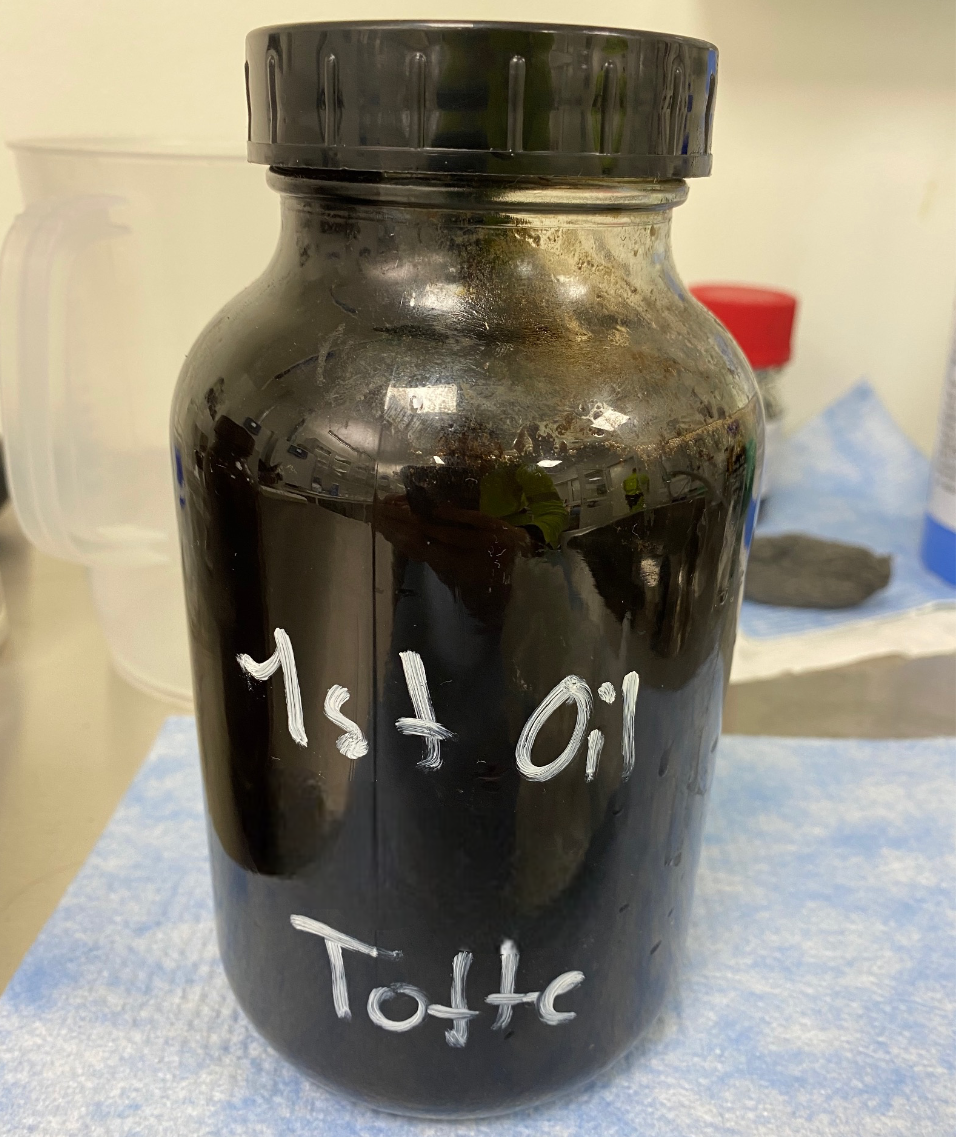

- Develop a world-class Advanced Biofuels Refining and Analytics Laboratory – our Advanced Biofuels Center (ABC) in Calgary Alberta. This lab is dedicated to developing know-how and processing capabilities associated with any Hydrofaction® produced biocrude facilitating the commercial processing of a wide range of waste feedstocks to certified finished fuels.

- Build a Next-Generation HTL Demonstration Plant at the Aalborg East facility. The pilot scale plant will be finished in 2026 and the demonstration scale plant will be ready in 2027.

- Develop essential elements of a “basic” engineering design package associated with a commercial-scale Hydrofaction® plant—our Standard Modular Plant Design (SMPD). Detailed design work occurs after specific sites are selected. Steeper’s SMPD documentation was then reviewed by global engineering firm, Hatch Engineering, validating key design elements.

- Confirm offtake agreements. Steeper has engaged in the process to sign MOU’s with major global fuel users that commits to delivery of substantial volumes of Hydrofaction® Oil. These commitments will support commercial projects around the world.